required accessoires

Prolyte Protrac PT-L600, upper profile, 6m

Description

- Theater traverse

- Alloy: EN AW 6082 T6 F28

- Profile: 60 diam.

- Coupling system: screws

- Town weight: 6,088 kg / m

SYSTEM DESCRIPTION

ProTrac is aimed at professional users from the theater and show industry.

It is an alternative to two-belt carriers (ladder traverses) as a replacement for load bars on brochure trains. ProTrac has high load capacity reserves and high lateral stability.

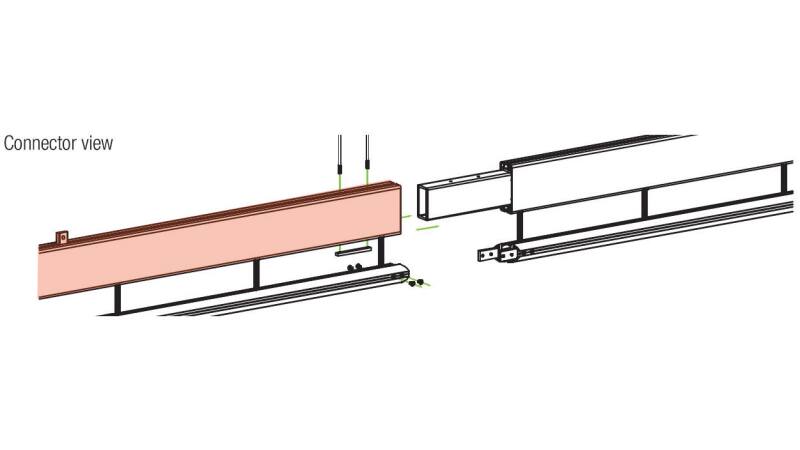

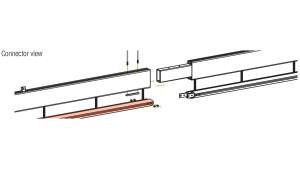

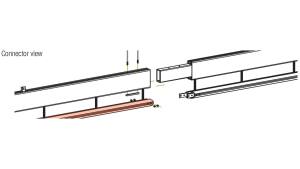

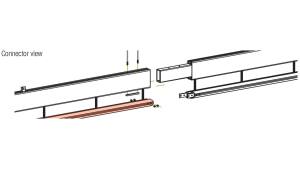

ProTrac consists of a rectangular upper extruded aluminum profile combined with a lower round aluminum tube or profile. Three types of lower profiles can be connected to the upper profile:

- Tube with slot profile 48.3 mm

- Tube with slot profile 48.3 mm, with integrated rail shelf for helmet 100 runners

- Tube with slot profile 60 mm, with integrated rail shelf for helmet 100 runners

The lower profile is connected to the upper profile with stud bolts. Hanging points for the ProTrac components slide into the slot in the top profile and are easy to attach thanks to a locking and loading system. ProTrac is a modular system.

Variable lengths can be connected via inner tubes that are screwed into place. The connection of two lower profiles takes place at 45 degrees to ensure perfect running. The ProTrac profiles are anodized black and have rubber caps at the ends. The top profile can be provided with additional holes of 50 mm (500 mm apart) to provide connections for integrated sockets.

DO

- Use only pre-stressed steel wires for hanging the flying rods

- Before the first movement, check the actual load on the flying rod

- Before the first movement, check that the load is suspended on the flying rod

- Ensure that the flight path of loads or supports is not blocked

- Make sure you use the correct type of washer for your steel wires

- Use only tested and certified hardware

- Keep a written logbook

DON'T

- Exceed the specified maximum permissible load

- The Pro Trac cantilever chair is more as stated

- in the structural report

- Use damaged parts or hanging devices

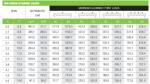

LOADING

- The allowable load shown applies to the entire Pro Trac system and applies to 48.3mm or 60mm downtubes.

- The permissible load only applies to the Pro Trac. Winch capacity and overall length must also be taken into account in an overall system.

- The total weight of 2 point loads in 2 adjacent fields should not exceed the maximum permissible capacity of the suspension cable points.

EXAMPLE

Winch/lifting force 750 kg. Length of ProTrac = 24 m.

Dead weight of Pro Trac = 216 kg.

Free loading capacity = 750 kg - 216 kg = 534 kg.

Point loads: 2 x point loads of 267 kg. Max. Evenly distributed load = 534/24 = 22.3 kg / m1